Understanding the HM88 Series: Key Features and Benefits

The HM88 Series represents a significant advancement in industrial manifold systems, catering to various sectors that require efficient and reliable fluid control. Developed with the latest engineering technologies, the HM88 is designed to meet rigorous industrial standards while optimizing process efficiency. When exploring options, hm88 provides comprehensive insights into the manifold’s specifications and capabilities, establishing itself as a go-to resource for professionals in the field.

What is the HM88 Series?

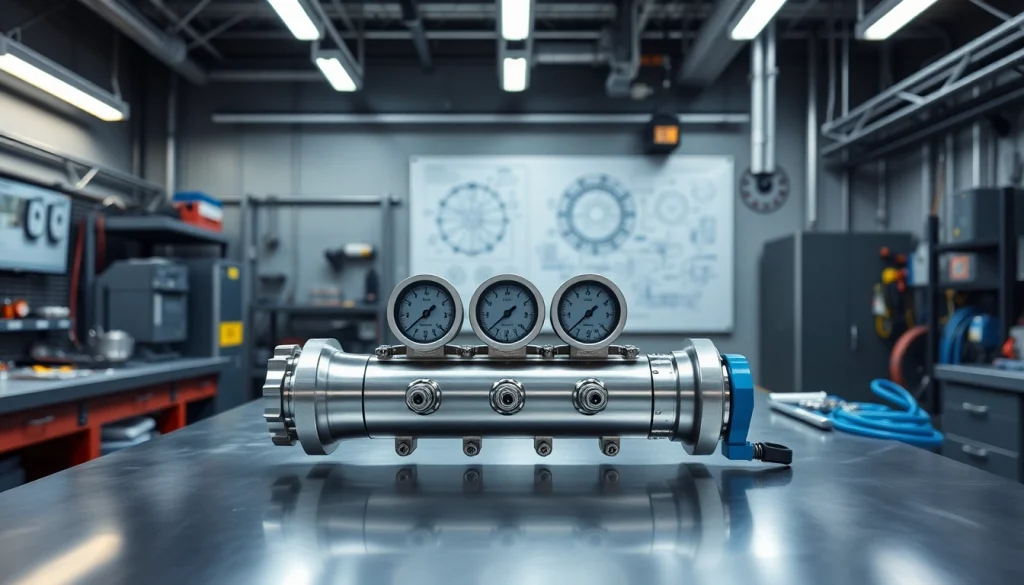

The HM88 Series consists of three-valve direct mount manifolds engineered for precise control and measurement of fluid pressures in various applications. Built with high-quality materials, these manifolds feature streamlined designs that reduce pressure drops and enhance overall system performance. The HM88 models are compatible with a wide range of differential pressure transmitters, making them incredibly versatile for industrial use.

How HM88 Improves Efficiency in Industrial Applications

Efficiency is paramount in industrial settings, where downtime can lead to substantial financial losses. The HM88 Series improves efficiency by enabling close-coupled mounting of differential pressure transmitters, which minimizes space requirements and installation complexity. The integrated design reduces the need for additional fittings, decreasing potential leak points and enhancing reliability.

- Space-Saving Design: The compact nature of the HM88 allows for installation in tight spaces.

- Reduced Installation Time: Simplified mounting reduces labor hours and costs.

- Enhanced Performance: Optimizes flow rates and lowers energy consumption.

Common Applications for the HM88 Manifold System

The HM88 Series is utilized across numerous industries, including oil and gas, chemical processing, and HVAC systems. Its reliability and precision make it suitable for applications such as:

- Measurement of fluid pressures in pipeline systems

- Regulating flow in hydraulic systems

- Monitoring environmental conditions in industrial plants

Installation and Maintenance of the HM88 Manifold

Proper installation and maintenance of the HM88 manifold are critical to ensure optimal performance and longevity. Following best practices not only extends the lifespan of the system but also guarantees reliable operational capabilities.

Step-by-Step Installation Guidelines for HM88

Installing the HM88 Series manifold requires adhering to specific guidelines to ensure a secure and efficient setup. Below are essential steps to consider:

- Preparation: Ensure that the installation area is clean and accessible.

- Mounting: Secure the manifold to the appropriate mounting bracket, ensuring it is level.

- Connections: Connect the manifold to the differential pressure transmitter and ensure all connections are tight to prevent leaks.

- Testing: Conduct a pressure test to verify the integrity of connections and functionality.

Regular Maintenance Tips for Optimal Performance

Routine maintenance is essential for the reliability of the HM88 Series. Adopting a proactive maintenance schedule can mitigate potential issues:

- Inspect seals and gaskets for wear and replace as necessary.

- Clean the manifold regularly to prevent clogging and buildup.

- Check for leaks and address them immediately to maintain system integrity.

Common Installation Mistakes and How to Avoid Them

Installation errors can lead to significant operational issues. Here are common pitfalls and tips to avoid them:

- Improper Mounting: Always ensure the manifold is mounted securely and aligned properly.

- Neglecting Pressure Testing: Always perform pressure tests post-installation to catch leaks early.

- Ignoring Manufacturer Guidelines: Follow all specifications provided by the manufacturer for best results.

Comparing HM88 with Other Manifold Systems

As the industrial manifold market expands, choosing the right system can be daunting. The HM88 Series stands out against its competitors due to its advanced features and reliable performance.

Strengths of HM88 Against Competitors

When comparing the HM88 Series to other manifold systems, several strengths emerge:

- Advanced Design: The integrated three-valve setup is unique, providing enhanced control.

- Durability: Manufactured from high-grade materials, the HM88 withstands harsh environments.

- Cost-Effectiveness: The reduced need for fittings and installation time lowers overall costs.

Cost-Benefit Analysis of Using HM88

Conducting a cost-benefit analysis of the HM88 Series reveals its advantageous pricing structures against competitors:

- Lower installation costs due to simplified processes.

- Reduced maintenance expenses owing to reliable performance and fewer failures.

- Long-term savings from increased efficiency and lower energy consumption.

User Testimonials: Why Choose HM88?

User satisfaction plays a vital role in establishing the credibility of the HM88 Series. Here are a few testimonials from industry professionals:

“Since switching to the HM88, our maintenance costs have dropped significantly due to its reliable design.” – Operations Manager, Chemical Plant

“The easy installation process and immediate improvements in efficiency made choosing HM88 a simple decision.” – Maintenance Supervisor, Oil Refinery

Future Trends in Industrial Manifolds: Looking Ahead to 2025

The industrial landscape is evolving, and so are manifold technologies. Keeping an eye on future trends is essential for businesses looking to stay competitive.

Emerging Technologies Impacting Manifold Design

Advancements in technology are shaping the future of manifold systems. Some trends to watch include:

- Smart Sensors: Integration of IoT sensors for real-time monitoring and data analysis.

- Material Innovations: Development of lighter, more durable materials to enhance performance.

- Modular Systems: Design trends focusing on modular structures for easier upgrades and maintenance.

The Role of Automation in Future Manifold Systems

Automation is becoming increasingly significant in industrial applications. Future manifold systems are likely to leverage automation for enhanced efficiency:

- Automatic pressure adjustment systems for varying operational demands.

- Remote monitoring capabilities to allow operators to manage systems from afar.

Predictions for Industrial Standards and Regulations

As industries evolve, so too do safety and operational standards. The HM88 Series is expected to adapt to these changes by:

- Complying with new environmental regulations aimed at reducing industrial waste.

- Incorporating safety features that align with stricter operational requirements.

Maximizing Performance with the HM88 Series

To leverage the full capabilities of the HM88 Series, users should adopt best practices that maximize performance while ensuring longevity in operations.

Best Practices for Using HM88 Effectively

Implementing best practices can lead to enhanced performance and reduced operational risks:

- Regularly train staff on proper usage and maintenance procedures.

- Utilize the manifold within its specified parameters to avoid failures.

- Document and review all maintenance activities for future reference.

Case Studies of Successful HM88 Implementations

Real-world case studies highlight the effectiveness of the HM88 Series in various scenarios:

- Case Study 1: A leading chemical manufacturer adopted HM88 systems and reported a 30% reduction in fluid leakage, significantly improving safety and compliance.

- Case Study 2: An oil extraction facility used HM88 manifolds and achieved a 15% increase in operational efficiency due to better process control.

Performance Metrics: Measuring Success with HM88

Measuring the performance of the HM88 Series can be done through various metrics:

- Reduction in maintenance downtime over a specific period.

- Increased flow rates compared to previous systems.

- Financial savings from reduced energy consumption and maintenance costs.